Powder Coating Articles

Ask Joe Powder (2)

Joe Powder answers to reader’s questions on aspects of the powder coating process.

This article’s subjrct:

Using powder coating after expiration date; Yes or No?

Hi Joe, I’m selling powder coating in south America. So now I have my questions with regard to powder coatings. But the most important is this. Can powder coatings be used past the expiration date given by the supplier?

Thanks,

Claudia Helsum,

Medellin, Colombia

Answer:

Hello Claudia, Thanks for the question. I have traveled and worked in Colombia and have very fond memories of my time spent there. I will be very happy to answer your question.

The stability of a powder coating is influenced by many factors. First, I must differentiate two distinct types of stability. Physical stability involves the requirement for the individual particles to resist clumping or sticking together. Chemical stability refers to a powder coating’s resistance to premature polymerization during storage and handling.

Physical stability is influenced by the melt point or more specifically the Tg (glass transition temperature) of the powder coating and the storage conditions. A powder coating with a low melt point will sinter and clump more readily than one with a higher melt point.

Accordingly, powders stored in high-temperature environments will clump more readily than those stored in cooler areas. Additionally, powders exposed to high-humidity environments tend to absorb moisture, which will also cause clumping. (Please note that most powders are supplied in moisture impervious containers and the exposure to moisture occurs after the package has been opened.) Clumping obviously makes a powder difficult to fluidize, transport and spray in an application system.

On the other hand, chemical instability causes a powder coating to chemically advance or polymerize during storage. Fast-reacting and low-temperature-curing powders can start to polymerize in high-temperature storage conditions. This premature chemical advancement reduces the melt flow of a powder coating, causing a more textured finish.

Both physical and chemical instability can be present in a powder coating. Typically, fast-cure (or low-temperature-cure) powders also have low melt points to help facilitate better melt flow at low cure temperatures. Consequently, these types of powders are most susceptible to clumping and chemical advancement and should be stored and applied in a climate-controlled environment. I recommend less than 27 ⁰C and 50 to 70% relative humidity.

Now to answer your question (are you asleep yet?). Standard curing powder coatings (175 -200 ⁰C) that have been stored in a reasonable environment can remain usable long past their “due date”.

Low-cure powders and those that have been stored in environments exceeding 27 ⁰C for long periods of time can suffer from clumping and chemical advancement. I would inspect (for clumps, etc.) then spray and bake a sample of any powder that is past its due date and make the determination yourself. If the finish is still within your requirement for smoothness and appearance (no blistering, dirt, etc) then I would continue to use it.

Claudia, I hope that this helps you. Someday I hope to return to Colombia to enjoy the beautiful weather, excellent food and wonderful people.

Peace,

Joe

Best powder coating primer for Aluminum:

Hello Joe, What would you say is the best powder primer to use on aluminum?

Thanks,

Alex Piehet

New Orleans

Answer:

Hi Alex, An epoxy-based primer will be best, although there are a few good epoxy-polyester primers out there as well. Do not use a zinc-rich primer, however – they are not designed for aluminum substrates.It is wise to undercure the primer before you apply the topcoat (if it’s a powder topcoat).

This way you achieve a better chemical bond between the coatings. It is also very important to apply the coatings over a very clean and preferably chemically pretreated surface.

Best regards,

Joe powder.

Camera coating; Liquid or Powder?

Hi Joe

Hey Joe, Go Bucks!

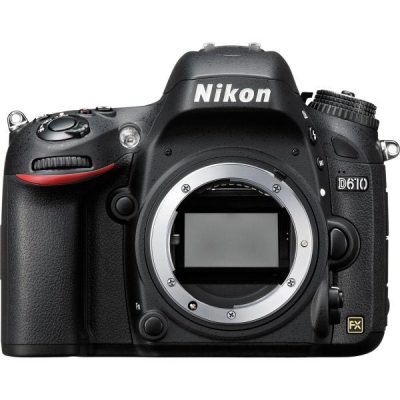

Hey there, my name is Sam Story I have this finish in mind that I am trying to find the industrial process that made it or a specific name for. Been searching for months with no luck. It is common on DSLR cameras. I have attached some examples to the email. Is this powder coating?

Answer:

Hi Sam, Thanks for contacting me and remembering us. The finish on that spiffy Nikon DSLR looks like a liquid coating. Let me break it down. The top and bottom caps of the camera body look to be a two coat, system. First a smooth dead matte black (obviously), Let it set and dry, then a splatter coat to give the semi-regular “bumpy” pattern. Liquid paint technologists sometimes alter the base coat (first coat) by thickening it then use it to create the splatter.

The body proper probably is coated with the same smooth dead matte liquid paint. The texture, as you probably can tell, is from the embossing of the metal.

So- there’s a high probability that the coatings are not powders. That said, the powder coating industry has developed a really awesome “Zero-Gloss” black powder for industrial photo imaging, machines.

Similar powder coating technology has been developed for a watch company out of Detroit.

If you need a special coating, just let me know. I can connect you to the right people.

Go Bucks.

Joe Powder

Reference:

Joe Powder, Polymers Paint Color Journal, Ask Joe Powder, VOL209-NO. 4653, August 2019.