Composite Articles

Advantages of using tissue fiberglass in production of composite parts

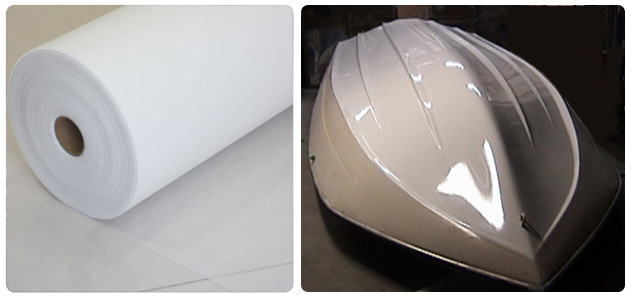

To achieve a smooth and glossy surface, and in order to increase the corrosion resistance and preventing destruction of composite and FRP parts, tissue fiberglasses are used as the first layer on the surface. These fiberglasses together with the resin, form a matrix and because of the fine and compact texture of the tissue, proper distribution and easy formation in the mold, it prevents the creation of air bubbles when applying Gelcoat, and prevent the composite part from blistering.

In composite parts the role of Gelcoat is same as skin for human! Despite of its low consumption, gelcoat holds the most important role in protecting composite parts against weather & environmental conditions. In case of using tissue fiberglass as the first layer and also correct choice of gelcoat, according to environmental conditions, service life of composite parts can be multiplied. When tissue fiberglass is not used in production, the air between the Gelcoat and the fiberglass act as a trap for water and moisture to penetrate, causing the surface to swell and composite part will be corroded and damaged over time.

By using these fiberglasses, provided consuming isophthalic gelcoats, in manufacturing launches, boats or other surfaces that are exposed to humid environments, water and UV corrosion resistance of composite part will be increased.

Therefore, considering the properties of tissue fiberglass and the proper usage of it, it is possible to avoid the cost of destruction and corrosion and the loss of parts significantly.