Powder Coating Articles

Ask Joe Powder (1)

Joe Powder answers to reader’s questions on aspects of the powder coating process.

This article’s subjrct:

Best powder coating primer for exterior environment:

Afternoon Joe,

I had a question about coating. What is the best powder coating primer to use as a base coat on fencing outdoor iron rails? We then applied gloss black as top coat, we use zinc rich primer as our base but the top coat and base is starting to peel off.

Thank you,

Joel Menchaca, Houston

Answer:

Morning Joel – This sounds like a serious problem. Using a zinc primer should be okay as your base coat (aka primer) as long as it’s processed properly. Please ensure that the iron rails are properly prepared before applying the primer .By proper preparation I am referring to first removing all “oils and soils”, then preparing the metal for the best adhesion of the primer. The O&S can be removed by solvent wipe (acetone works well) or alkaline cleaner followed by a clean water rinse. Pretreating the metal is next and can be accomplished by media blasting (remember to use only clean media) or a chemical pretreatment, such as iron phosphate or zirconium/ silane solution. Clean rinsing with deionized water or water processed through reverse osmosis is recommended to ensure the best surface for the primer to adhere to.

After applying the primer it is wise to partially cure or “gel” the powder. Best topcoat adhesion is achieved over an incompletely cured primer. So reduce the recommended primer bake time by 50% and proceed to top coating. Bake the top coated rails per the recommended powder bake as disclosed on the Product Data Sheet provided by your powder supplier.

If you’re still having adhesion issues after following the recommendation above, then I would switch to a non-zinc primer. They work as well as most zinc-rich types and are much easier to spray. In addition you get significantly more coverage per pound of powder because the specific gravity of a non-zinc primer is considerably lower than that of the zinc rich material. We’ve seen excellent corrosion resistance of the newer non-zinc primers in our laboratory. Remember that clean, well pretreated metal for optimal inter coat adhesion.

Best of luck,

Joe

Powder coating haziness in batch ovens:

Dear Joe,

We encountered haziness when curing our profiles with a batch oven, yet the same powder works well with a conveyor oven. The powder with anti-oxidant as we were told. However, no improvement has been observed with the improved version. What could be the root cause of the above? The powder is an outdoor TGIC- high gloss white.

Thanks in advance,

Lee Hwa Goh, Singapore

Answer:

Hi lee Hwa – thanks for the question. This has, to be frustrating. Here are my thoughts and questions:

How well is the exhaust in your batch oven? When you open the batch oven door is there a hazy cloud? If there is inadequate exhaust, byproducts of combustion may be accumulating in the oven. In addition a small percentage (~0.5 to 1.0%) of nearly all powders evolve at elevated temperatures in an oven.

Another possibility is “blooming”. Some polyester powders emit a hazy surface film at certain bake conditions. It usually occurs with long low temperature bakes (βg 150°C or below). If this is the case, then increase the bake temperature 10 or 15°C and see if the problem is eliminated. The use of an antioxidant usually does not improve a hazy film surface. Antioxidants are used to minimize color shifts due to polymeric degradation.

Please let me know if any of these suggestions help.

Best regards,

Joe Powder

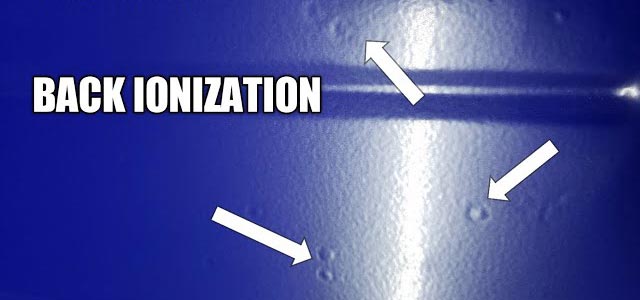

What is “Back Ionization”:

Hi Joe

One customer mentioned a back ionization problem when blending a fluoropolymer with an acrylic resin. Can you explain to me what back ionization is?

Thank you,

Dr. H wang, Exton, Pennsylvania

Answer:

Hi Dr Wang,

Back ionization occurs when excess charge builds up on a powder coating layer. It is usually associated with a poor ground or applying powder to a semi-insulated surface.

The insulation can be due to a previous coat on the surface like a primer.

It also occurs when someone tries to pile on too thick a coat too quickly and the charge doesn’t have time to dissipate to the ground. That said, different powders attract and dissipate charge differently. It probably has to do with the dielectric constant of the resins and the influence of pigments, inert fillers and additives.

Ok, so that’s the theory.

Sincerely.

Dr Joe

Reference:

Joe Powder, Polymers Paint Colour Journal, Ask Joe Powder, VOL208-NO. 4647, December 2018.