It is necessary and essential to pay attention to the fabrication and protection of the gelcoat because a composite part must be durable over time when exposed to UV, heat, cold, moisture, dust, oxygen and other gases (outdoor conditions). If the selection of gelcoat or its application is not done correctly, the mentioned factors can cause the decomposition and destruction of composite materials.

The table below, lists some of the common problems that may occur with composite parts, with the possible cause of the problem, and in the last column of the table, the items that should be checked and the solution to overcome the problem is provided:

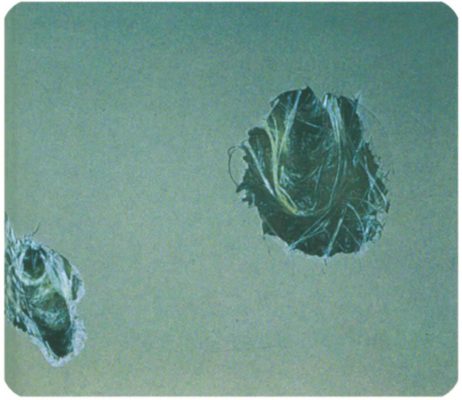

Air bubbles

| Example |

Problem |

Cause |

Solution or item to check for |

|

Air bubbles |

Air pockets |

|

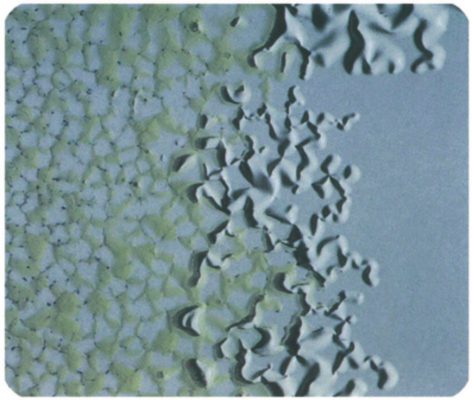

Alligatoring

| Example |

Problem |

Cause |

Solution or item to check for |

|

(a wrinkling of the gel coat, that looks like alligator hide)

Before Laminating After or during lamination, or a second application of gelcoat

|

- Raw catalyst, Solvent, Water or ‘Cured’ over-spray.

- Thin gel coat, Insufficiently cured gel coat.

|

|

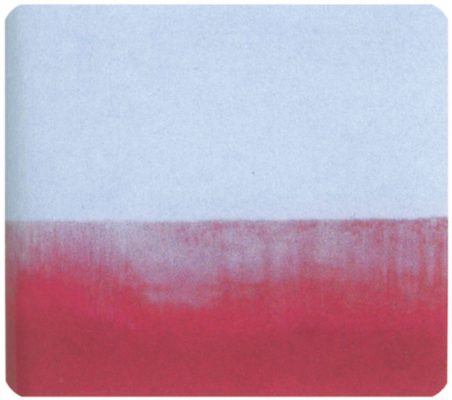

Bleeding

| Example |

Problem |

Cause |

Solution or item to check for |

|

one colour shows on another |

- Fresh gel coat sagging over ‘cured’ gel coat

|

- Check sag resistance of ‘fresh’ gel coat.

- Spray fresh gel coat sooner.

Spray this film of fresh colour over the ‘wet’ base coat.

|

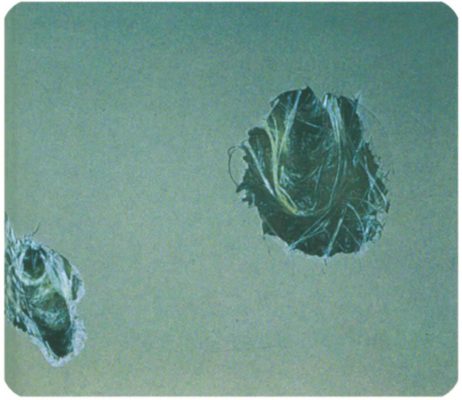

Blisters

| Example |

Problem |

Cause |

Solution or item to check for |

|

Appear shortly after part is pulled, especially when put in sun.

Appear after part in field.

Water Blisters |

- Unreacted catalyst or under cure.

- Solvent, water or oil.

|

- Check % catalyst, catalyst overspray, mixing and leaks.

- Check air-lines, material, and rollers.

- Check roll out.

- Check catalyst levels, film thickness – 450 ±100µm.

|

|

Appear shortly after part is pulled, especially when put in sun.

Appear after part in field.

Water Blisters |

- Air pockets

- Unreacted catalyst.

- Solvent, water or oil.

- Various

|

- Check air lines, material, and rollers

|

Chalking

| Example |

Problem |

Cause |

Solution or item to check for |

|

Chalking

(gel coats will oxidise/chalk over an extended period of time; degrees of chalking is directly related to the environment).

Dry, chalk-like appearance or deposit on surface of gel coat (Premature) |

- Cure

- Contamination

- Insufficient

- Poor mould condition

|

- Check Section on Blisters and Boil Test

- Under or over catalysation giving incomplete cure.

- Check catalyst level, film thickness water and solvent.

- Surface soil picked up from atmosphere.

- Wipe buffed area with solvent rag, if gloss stays, it is okay. If gloss dulls down, part needs more

- Reduce sanding and buffing requirement on parts by keeping mould in good condition.

|

Checking (mud cracking)

| Example |

Problem |

Cause |

Solution or item to check for |

| – |

Single or groups of independent or crescent-shaped cracks |

- Poor integrity of the gel coat film.

|

-

Trapped vapour or incompatible liquid which blows through the gel coat film on ageing. Check catalyst level.

-

Check for water, solvent, etc.

- Chemical attack.

|

Craters while spraying

| Example |

Problem |

Cause |

Solution or item to check for |

| – |

Craters while spraying |

- Large particles in the gel coat.

- Equipment

|

|

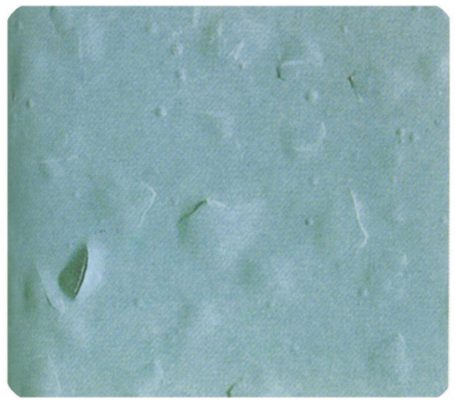

Dimples in the gel coat surface

| Example |

Problem |

Cause |

Solution or item to check for |

|

Dimples in the gel coat surface |

|

- Check for water, solvent, or improperly mixed catalyst.

- Overspray.

- Seedy resin.

- Excess binder on the glass mat.

- Thin laminate or gel coat.

- Very dry laminate

- Pin air entrapped in laminate.

- Post curing of the laminate.

|

Dull gloss

| Example |

Problem |

Cause |

Solution or item to check for |

|

on gel coat when part is pulled

After part is pulled |

-

Rough mould

- Mould build-up

- Polystyrene build-up

- Dirt or dust on mould

- Solvent or water

- Raw catalyst

- Rough PVA or wet PVA

- Insufficiently cured gel coat or laminate.

|

- Polish out mould.

- Wash and buff with cleaner; in most

instances, what is called wax build-up is

actually polystyrene build-up and should be treated as such

- Sand or scrub with brush and strong solvent, read precaution on solvent before using.

- DO NOT USE STYRENE

- Clean the mould. It is best to clean in the spray booth just prior to gel coating. Timespan should be as short as possible between cleaning and gel coating.

- Use a tack rag.

- Check for solvent or water.

- Drain water traps regularly.

- Start catalyst flow from gun away from the

mould.

- Only catalysed gel coat should be sprayed in

the mould.

Check spray technique. Allow longer to dry.

- Correct excessive or insufficient catalyst level

in gel coat and laminate.

- Wait longer before pulling.

- Check for low temperature (minimum of 15°C).

- Check for contamination; water, oil, or solvent.

|

Dull or soft spots, at random (continued)

| Example |

Problem |

Cause |

Solution or item to check for |

| – |

Dull or soft spots,

at random (continued) |

- Gel coat uneven

- Catalyst poorly mixed into either gel coat and/or laminate.

- Trapped solvent in gel coat and/or laminate

- Trapped water in gel coat and/or laminate

- Insufficient catalyst

|

|

Fading

| Example |

Problem |

Cause |

Solution or item to check for |

|

Fading

(also see water spotting)

See section on Weathering. |

- Poorly cured gel coat

- Improper cleaners or chemicals

|

|

Material gelled in container

| Example |

Problem |

Cause |

Solution or item to check for |

|

Material gelled in container |

|

- Use partially filled container first, keep

covered, rotate stock.

|

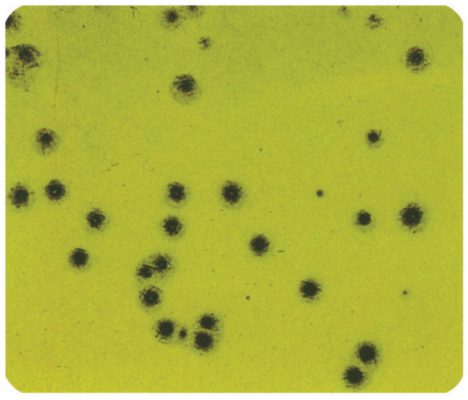

Pinholes

| Example |

Problem |

Cause |

Solution or item to check for |

|

Pinholes |

|

- Too high gel coat delivery rate.

- Not enough atomising pressure

|

Fibre pattern in parts

| Example |

Problem |

Cause |

Solution or item to check for |

|

Fibre pattern in parts |

- Insufficient cure

- Transferred from mould

- Glass Cloth

- Woven roving

- Gel coat too thin

- High exotherm of laminate

|

- Correct excessive or insufficient catalyst level in gel coat and/or laminate.

- Wait longer before pulling.

- Do not pull while laminate still has heat.

- Check for low temperature.

- Check for contamination by either water, oil or solvent.

- Refinish mould

- Too close to the gel coat. Should have 2

layers of mat or equivalent chop between gel coat and cloth.

- Too close to the gel coat. Should have 3

layers of mat or equivalent chop

between gel coat and woven roving.

- Use 450 (±100)µm wet.

- Cure laminate slower. Laminate in stages.

- Use lower exotherm laminating resin.

|

Fish Eyes

| Example |

Problem |

Cause |

Solution or item to check for |

|

Fish Eyes |

|

- Drain air lines.

- Check mould release wax.

- Check lubricating materials used within

the equipment.

- Use tack rag.

- Use 450 ± 100µm wet, built up in 3

passes.

- Old material – rotate stock.

|

Material gelled in container

| Example |

Problem |

Cause |

Solution or item to check for |

| – |

Material gelled in container |

|

- Use partially filled container first, keep

covered, rotate stock.

|

Pigment darting or specks

| Example |

Problem |

Cause |

Solution or item to check for |

|

Pigment darting or specks |

- Contamination.

- Foreign particles

|

- Clean pump and lines

- Strain and keep material covered. Keep overspray minimised. Be sure moulds are clean

- Spray

perpendicular to mould surface.

|

Pigment separation, (or mottling)

| Example |

Problem |

Cause |

Solution or item to check for |

|

Pigment separation, (or mottling) |

- Pigments separate from each other

|

- Check for contaminates such as water or solvent.

- Dirty equipment.

- Dry overspray. (Keep a wet line).

- Excessively applied gel coat causing sagging.

- Excessively high delivery rates causing a

flooding onto the mould surface.

|

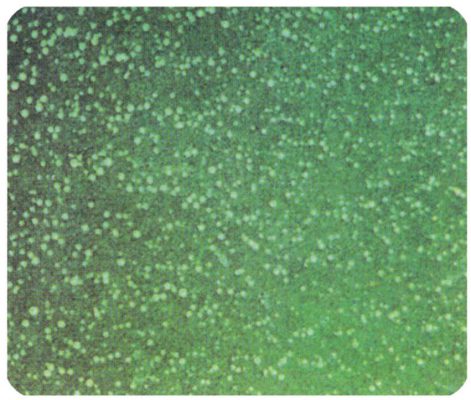

Porosity

| Example |

Problem |

Cause |

Solution or item to check for |

|

Porosity |

- Not enough atomising pressure.

- Entrapped air

Wrong catalyst

- Gel coat film thickness

- Formulation

- Water or solvent

- Pump

- Cavitation

- Excessive mixing

|

- Wrong air pressures. Too high tends to yield fine porosity; too low will produce larger surface porosity.

- Check gel coat vendor of recommendation.

- Applied too thick; use 450 ± 100µm wet. Apply in 2-3 passes.

- Improper viscosity and/or resin solids.

- Check with vendor Check for contamination.

- Check pump for air leaks.

- Mix once a day for 10 minutes only.

|

Pre-release

| Example |

Problem |

Cause |

Solution or item to check for |

|

.Occurring after cure.

Observed by seeing a sharp

distinct line (will not necessarily

feel the line), with increased

fibre pattern on the side of

the line that pulled away

sometimes referred to as

<<heat>> or <<shrink>> marks. |

- Mould release

Too long of cure

- Laminate curing too fast.

- Build laminate in stages.

- Wrong type resin

- Laminate curing uneven.

|

- Type and amount on the mould.

Laminate sooner – don’t tap or jar the mould.

- Check for proper catalyst level.

- Too high in exotherm.

- Low resin solids.

- Uneven laminate thickness.

- Check resin to glass ratio. Resin drain-out or puddling.

|

Splotches

| Example |

Problem |

Cause |

Solution or item to check for |

| – |

Splotches

after parts are

sanded and buffed

also referred to as ‘leathery’,

‘pebbly’,’chicken skin’ |

- Overspray

- Not maintaining a wet line

- Cure

|

- Do not allow overspray to accumulate

- Spray ‘laps’ within five minutes.

- The total film must cure as a total

homogenous film rather than several

independently cured thin films.

|

Resin tearing (or resin separation)

| Problem |

Cause |

Solution or item to check for |

Example |

|

Resin tearing (or resin separation). |

- Pigments separate from resin.

- Application.

|

- Check for sources of water. Improper spray techniques creating excessive

overspray droplets and flooding. Can be

aggravated by long gel time and sagging.

- Do not allow overspray to dry – keep a wet line.

|

| – |

Sags and runs |

- Excessive gel coat Spray techniques

- Low Viscosity

Mould wax

- Other

|

- Apply 450 ± 100µm.

- Wet. Atomising air is pushing and blowing the gel coat.

- Not enough styrene is being volatised. Check viscosity and thixotropic properties.

- Over-agitated. Material was reduced, but should not have

been.

- Silicone content too high.

- Jarring the mould before gelation

|

Delamination

| Example |

Problem |

Cause |

Solution or item to check for |

|

Delamination

In spots Large area |

- Contamination

- Gel coat too fully cured

- Contamination

- Unbalanced laminate

|

- Check for dust, solvent, moisture, catalyst getting onto gel coat surface, creating areas that will not adhere.

- Check for high catalyst level. Letting the gel coat cure too long, such as overnight. Skin coat, rather than leave on the mould for long periods of time.

- Excess mould release wax, or wax in the gelcoat.

- Dry fibreglass

|

Pre-release of the gel coat

| Example |

Problem |

Cause |

Solution or item to check for |

|

Pre-releaseof the gel coat;

. during cure causing obvious surface distortion

and low gloss |

- High catalyst level.

- Low catalyst level.

- Uneven and/or too thick film

- Gel coat allowed too long to cure.

|

- Calibrate equipment and decrease catalyst.

- Calibrate equipment and increase catalyst

- Check thickness, not to exceed 600µm, wet.

- Ensure a consistent film thickness.

- Gel coat should not be allowed to set on the mould for more than a few hours without laminating at least a skin coat.

- Varies with temperature should be laminated within same day.

- Check with manufacturer. Do not add styrene without their approval.

- Improperly dispersed catalyst.

- Check for contamination by such elements such asacetone, water, oil.

|

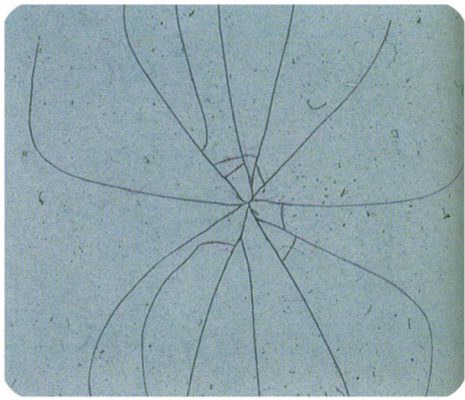

Cracks

| Example |

Problem |

Cause |

Solution or item to check for |

|

Spider cracks radiating out from a central point or in circles (Reverse impact) |

- Impact from laminate side

- Excessive gel coat film thickness

- Mould mark

|

- Check on handling and demould procedures. Caution people about hammering on parts.

- Use a thickness gauge. Do not go over 600µm.

- Defect in the mould.

|

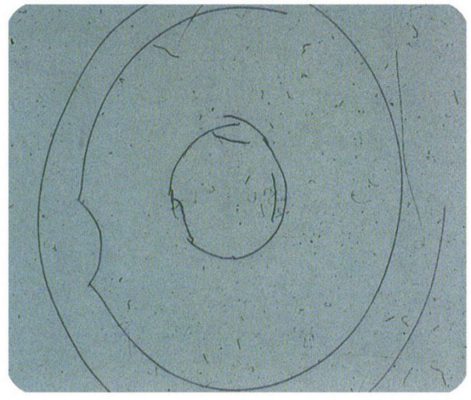

Frontal Impact

| Example |

Problem |

Cause |

Solution or item to check for |

|

Frontal Impact |

|

|

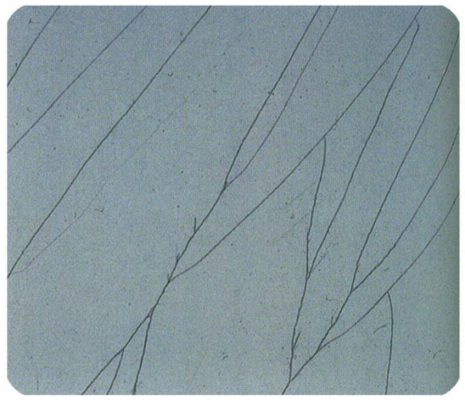

Stress Cracks (Cracking in parallel lines)

| Example |

Problem |

Cause |

Solution or item to check for |

|

Stress Cracks (Cracking in parallel lines). |

- Stress due to flexing

- Mould mark

|

- Excessive gel coat thickness.

- Laminate too thin.

- Pulled too green; laminate undercured.

- Demoulding or handing procedures.

- Sticking in the mould.

- Defect in the mould.

|

Softness

| Example |

Problem |

Cause |

Solution or item to check for |

| – |

Softness |

- Soft gel coat film which can be easily marred.

|

- Incomplete cure of gel coat.

- Check catalyst levels, contaminants

and film thickness.

|

Water spotting

| Example |

Problem |

Cause |

Solution or item to check for |

|

Water spotting |

- Usually caused by exposure with a combination of excessive heat and moisture.

- Poorly cured gel coat.

- Certain chemical treatments

such as chlorine and/or cleaners.

|

- Use only a product recommended for the particular application. Improper shrink-wrap. Use only product (and recommended procedures)

Applicable to gel coats.

- Check for both over and under catalysation.

- Misuse of these chemicals,

Allow 1 week ambient cure before service.

|

Gel coat yellowing

| Example |

Problem |

Cause |

Solution or item to check for |

|

(gel coat yellows rapidly

and unevenly when exposed to sunlight and/or heat and moisture).

See section on Weathering |

- Polystyrene/wax build up on the mould which has

transferred to the part during moulding.

- Inadequate gel coat cure: See section on Weathering

- Improper catalysation which results in inadequate

cure of the gel coat.

- Contamination such as solvent, moisture or oil.

- Improper or unauthorised adjustment of the gel coat.

- Pre-release

- Excessively hot resin – rich laminates.

- Resin tearing

- Uneven gel coat film thickness

- Cleaning the finished part with an alkaline cleaner.

- . Holding gun too close to the mould.

- Spraying in one pass

- Insufficient atomisation.

|

- Perform a regular mould-cleaning programme. Do not clean mould with styrene

or used/dirty/reclaimed solvent.Check catalyst (bad or old lot batch) and catalyst level. Use only a recommended catalyst

and maintain the proper level of catalysation. (See Product Data Sheet).

These contaminants will affect the gel coat’s cure. Look for moisture or oil in air lines,

moisture or other contaminants in solvents

used to cut the catalyst or other sources of

contamination.

- Do not add any material (other than a recommended Methyl Ethyl Ketone Peroxide catalyst) to the gel coat without the advice of a Cray Valley representative. The addition of solvents or excessive addition of styrene,

inhibitors, accelerators, etc.,

will adversely affect the gel coat’s cure and therefore its resistance to yellowing.

(Contact your Cray Valley representative if adjustment seems necessary).

- Do not apply gel coat at temperatures below 15°C Permanent undercure of the gel

coat may result. Old material may be slow in gel and cure and will need adjustment.

Contact a Cray Valley representative.

Provide adequate air circulation for <<deep-well>> areas where styrene vapours

may collect.

- Most of the conditions which cause prerelease will also result in unusual gel coat yellowing; i.e., uneven gel coat thickness,

uneven catalysation, uneven film gel and cure, etc. Check for and eliminate any pre-release tendencies.

- Good laminating techniques must be followed.

This is especially true in deep well areas where the gel coat is not likely to cure adequately.

Unusually ‘hot’ laminates at this point in the gel coat’s cure may result in permanent undercure and more yellowing of the gel coat.

- Overspray, excessive film build, flooding or contamination, all of which can result in vehicle/pigment separation. A concentration of the gel coat vehicle on the surface of the part will result in more rapid yellowing of the finished part.

- Avoid flooding the gel coat or applying excessively thick gel coat. Maintain the recommended 450 ± 100µm wet film coverage.

- Excessively thick gel coat films will yellow more.

- Do not use any strong alkaline cleaner (such as ammonia or other cleaner having a pH greater than 9) for cleaning a gel coat surface. A weathered gel coat can be yellowed by such cleanrers.

- Maintain proper distance.

- Spray in multiple passes.

- Gel coat must be atomised to a fine particle.

|

From the “Composite Industry Guide” book pages 57-69

Iran Composite Association